MDF - interior wall panels - 8mm

Read the instructions carefully before the installation of the interior wall panels

Before installation

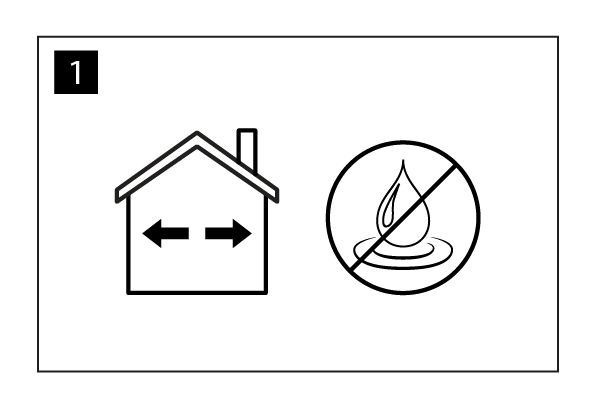

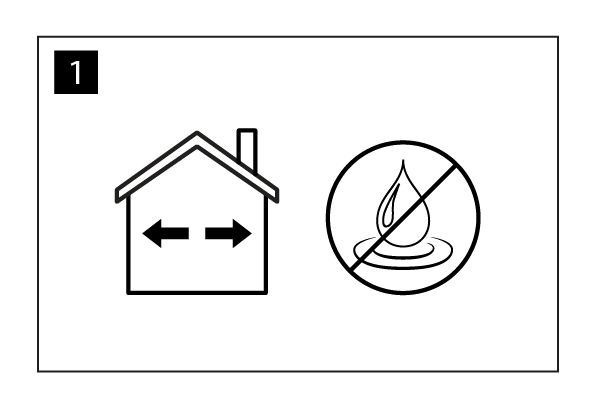

- Note that the interior panels are meant only for indoor use and they must not be in direct contact with moisture.

- Interior wall panels are not suitable to be installed to the ceiling.

- Any faults in the materials shall be reported to prior to the installation.

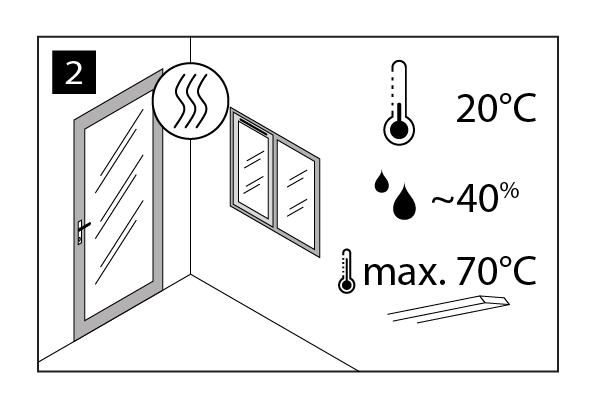

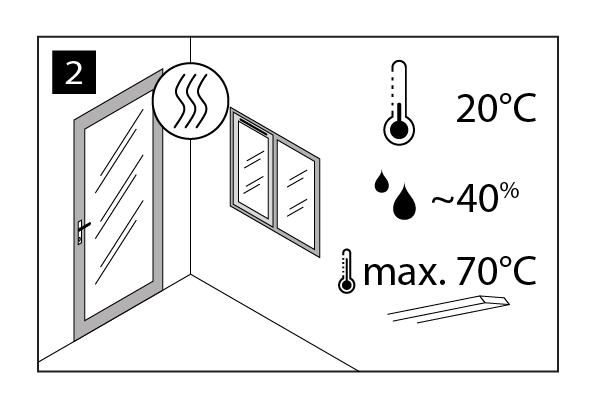

- The interior panel suits only for premises where the room temperature and humidity are normal, approx. 20°C, and the relative humidity is approx. 40%, i.e. the walls and the ceiling of the room shall be dry with window glasses and doors installed.

- Interior panels should not be exposed to continuous temperatures of over 70°C.

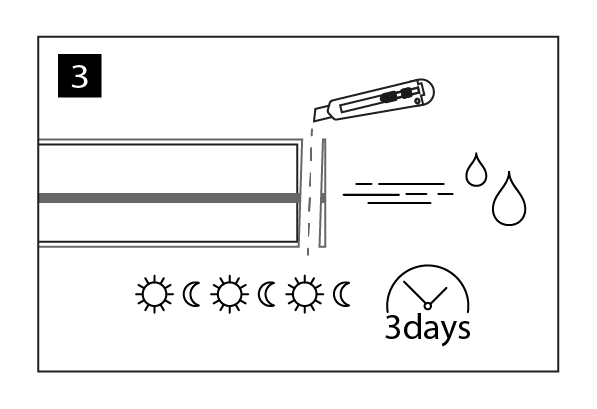

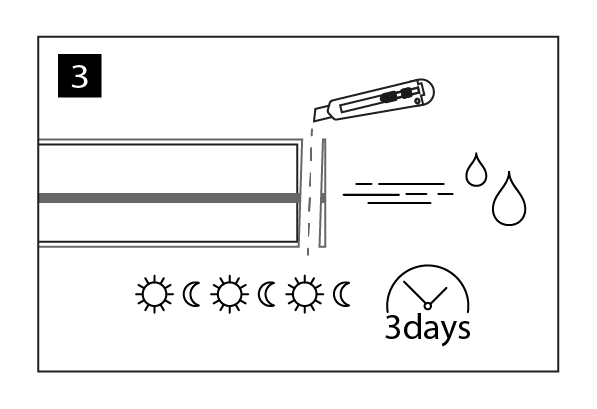

- The temperature and humidity of the interior panels shall be let to stabilise to the same temperature and humidity with the installation environment for three days before the installation. The packaging does not have to be totally removed. It is enough that you make a hole to the ends of the packages from where the humidity can be removed.

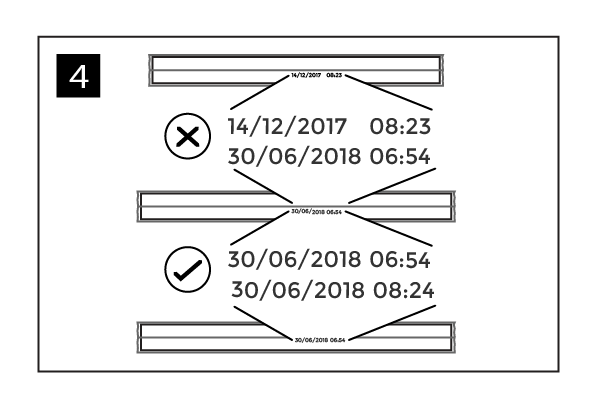

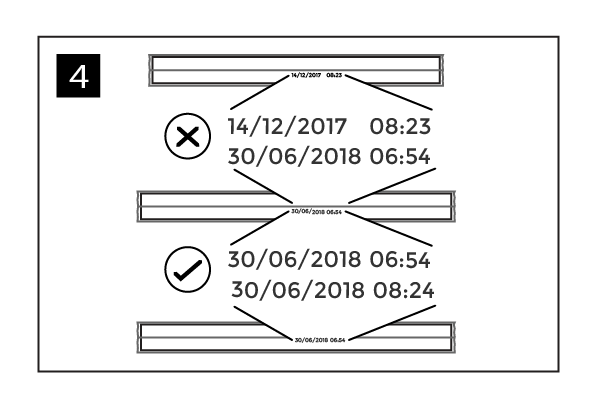

- Large surfaces should be made of the same production batch. The batch number can be found on the bottom interior panel of the package.

Installation

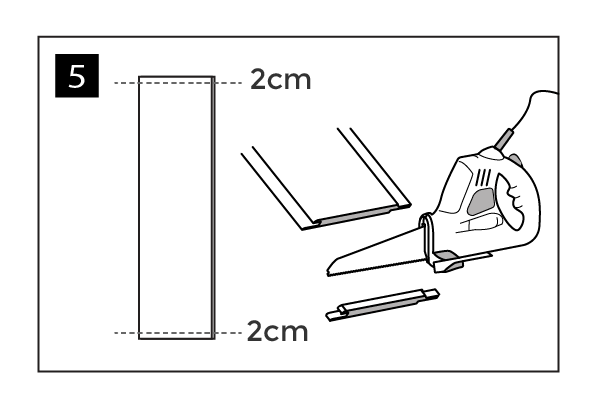

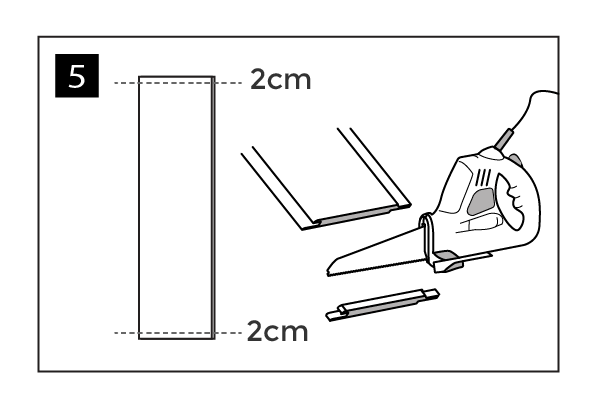

- The product is oversized, which allows a small tear in the film surface and skew (2 cm) within the dimension. Sawing the end cuts of the product, you make a successful installation and a sleek finish.

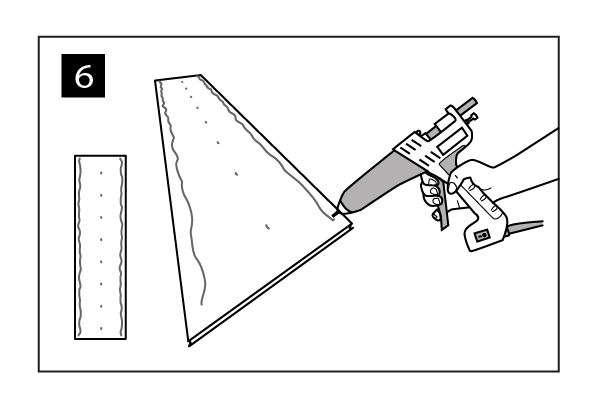

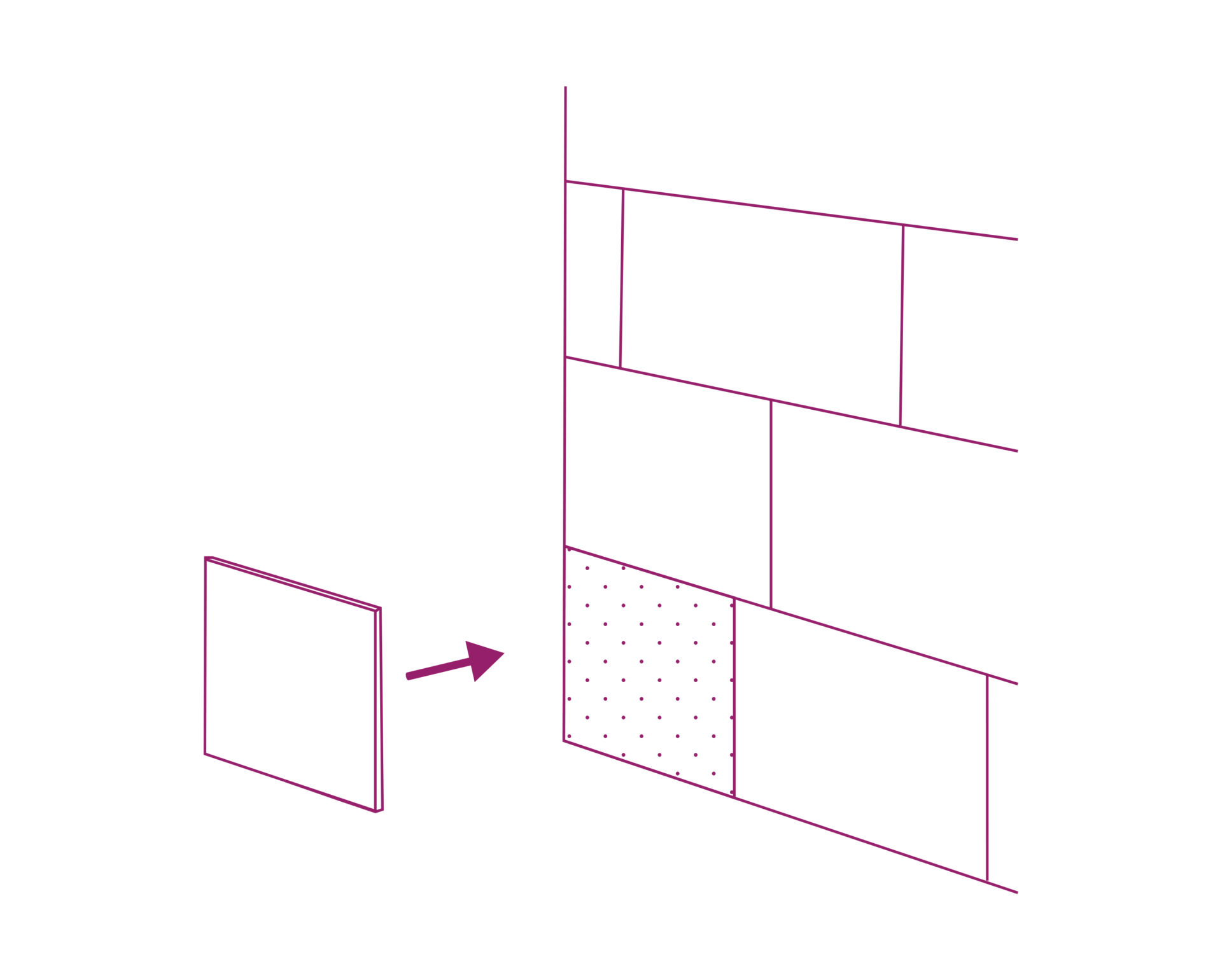

- Make a continuous stripe of glue to the both long sides of the panel and spots of glue to the middle of the panel.

- Check the suitability of the glue used with the glue manufacturer.

- The interior wall panels can be attached to plasterboard or directly to the old surface. Make sure the sufficient fastening of the bottom surface.

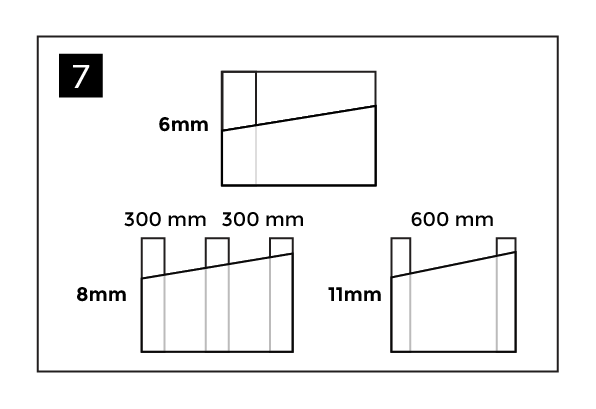

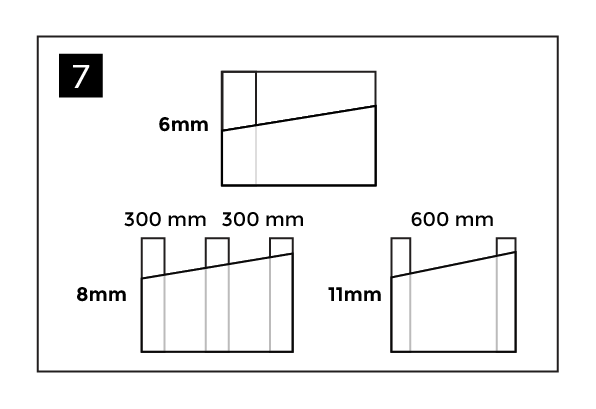

- 8mm interior wall panels can also be attached directly to the top of the supporting rails if the distance from centre to centre is 300mm.

- Interior wall panels must be installed parallel to the joists.

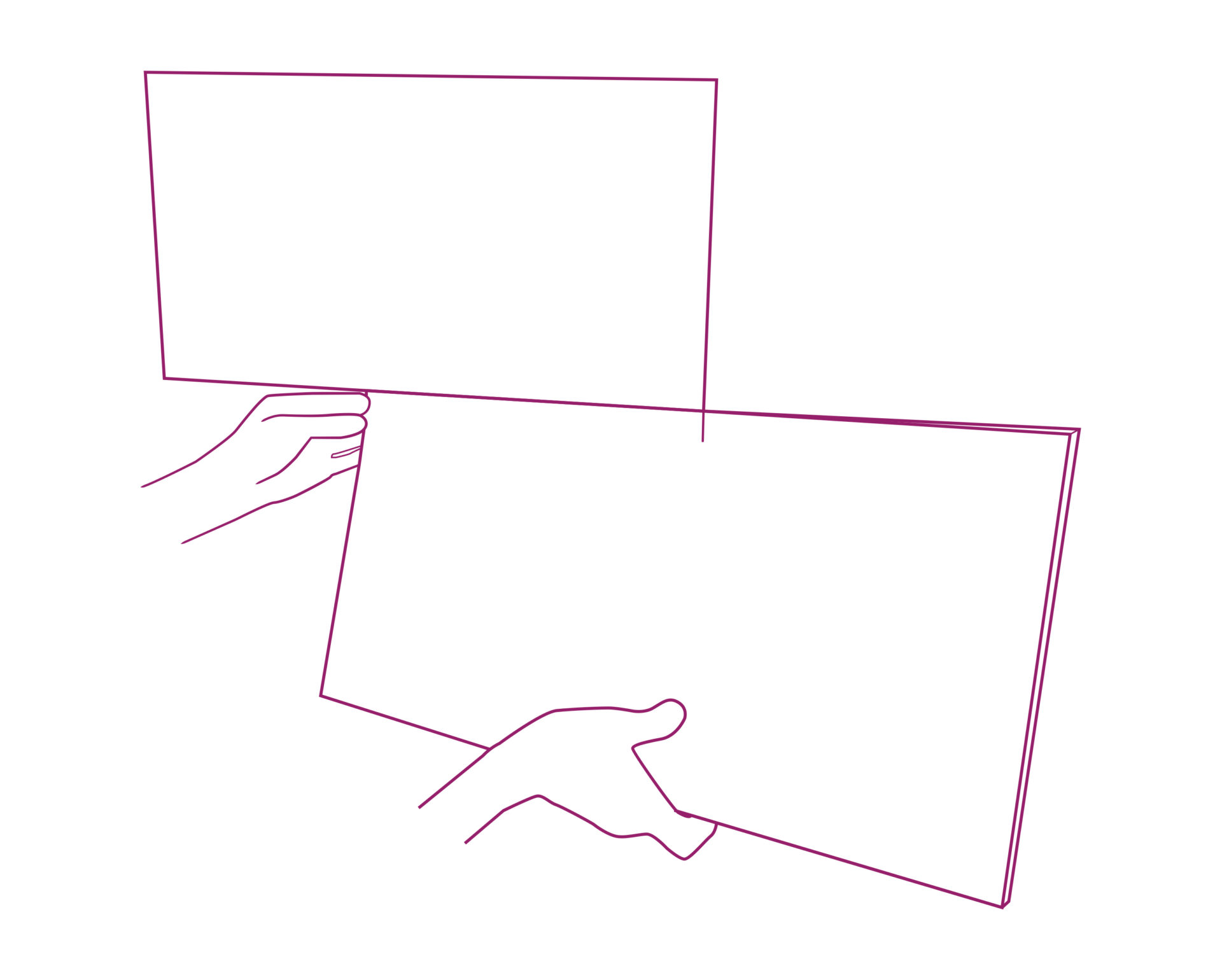

- To facilitate the installation, bring the board slightly over the already installed board. Pull the board backwards until the boards are at the same level, and push in to the tongue and groove joint.

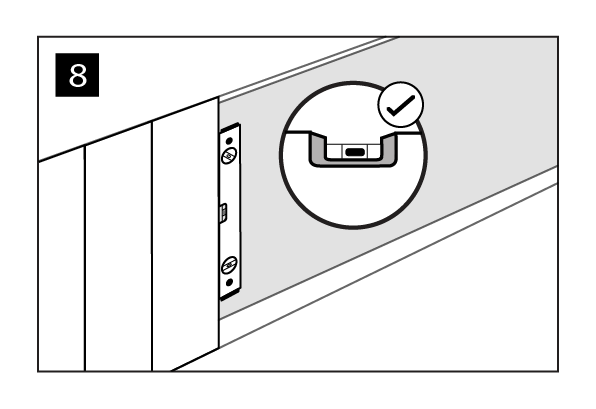

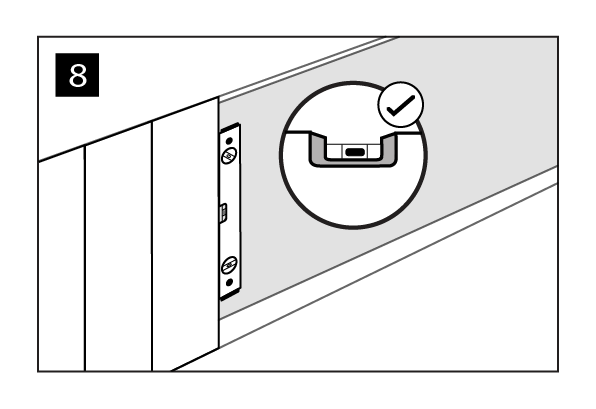

- Using a spirit level the panels can be installed straight. Installing the first panel straight is important to make the installation progress correctly.

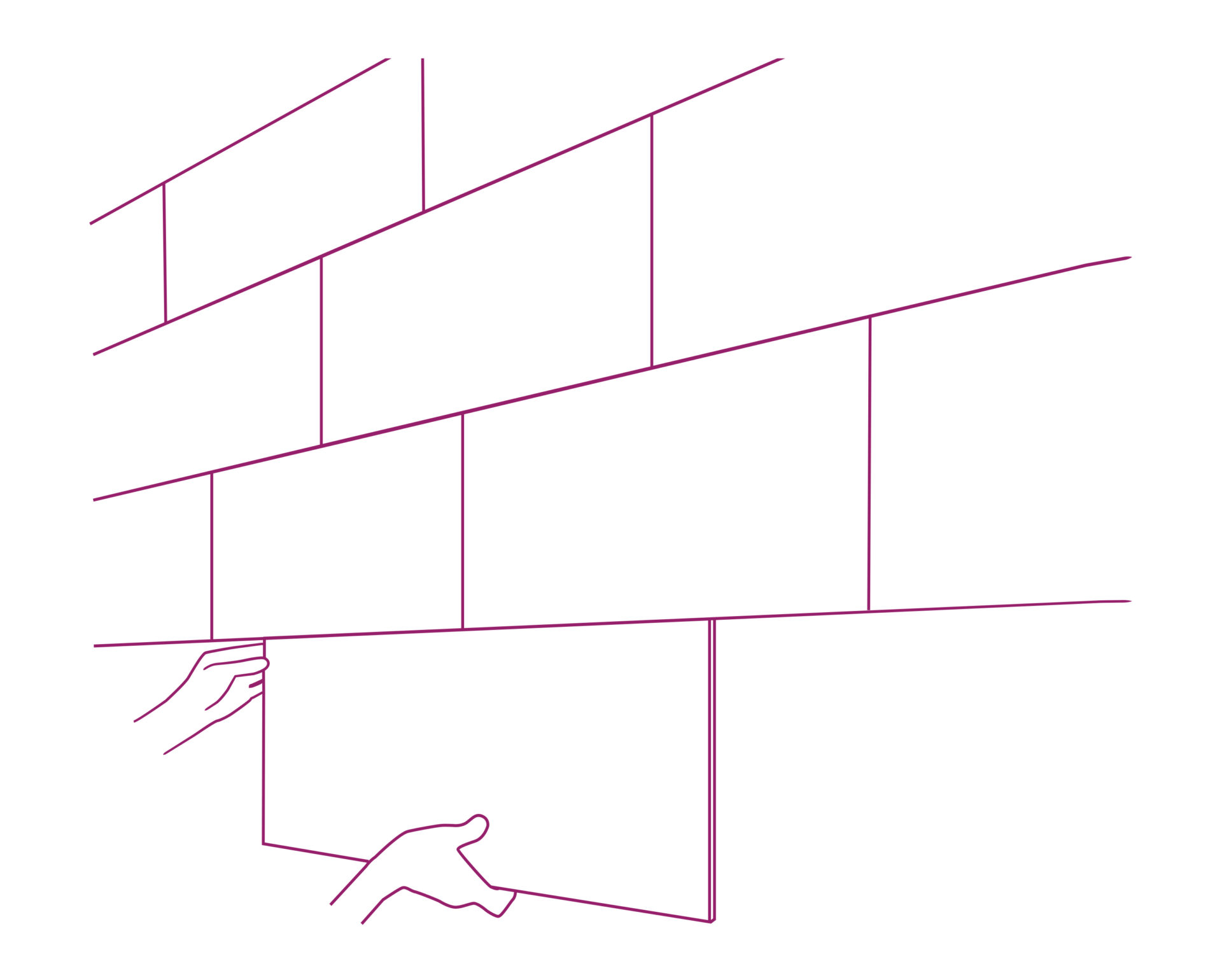

- Tongued and grooved wall panels are attached with a staple gun. The distance between the staples should be approx. 300 mm. Secure the fastening by gluing the panel according to the instructions.

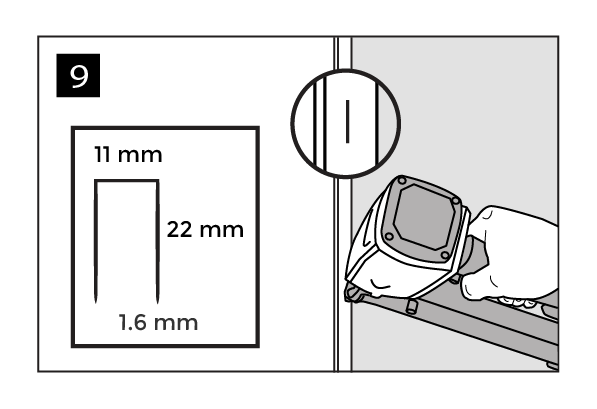

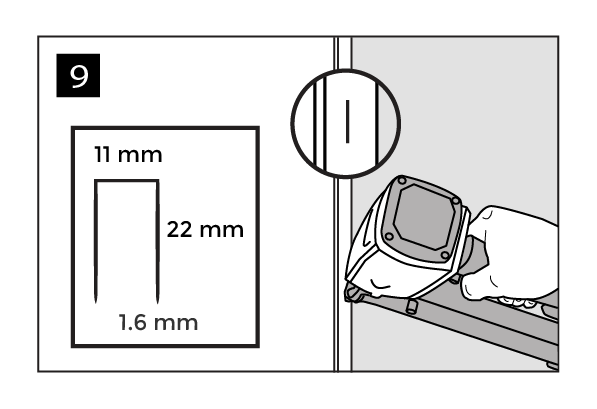

- Use at least a 22 mm long, 11 mm wide and 1,6 mm thick staples. The staple is shot diagonally to the lower intruding tongue of the female groove.

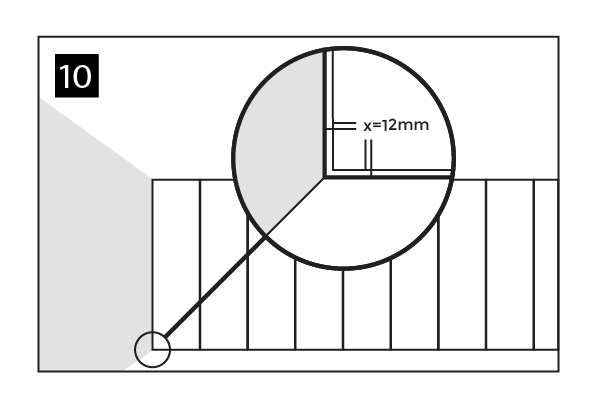

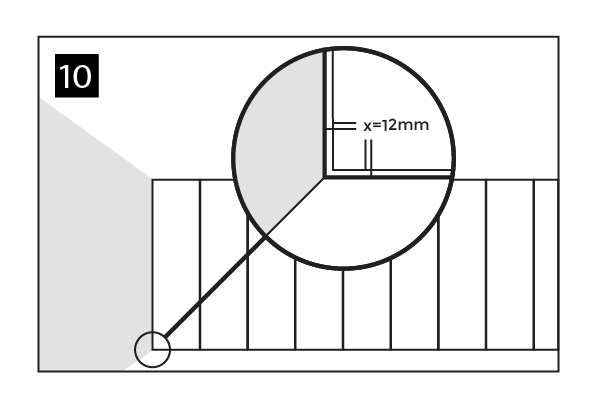

- Leave a minimum expansion room of 12 mm between the interior panels and the wall or some other surface limited to the panel. If the length or the width of the face is over 6 metres, add 2 mm of the expansion space for each extra metre.

- The wall sockets can be be raised to the same level with the wall surface with a heightening ring.

- The seam is covered by ceiling mouldings, baseboards and universal moldings.

Maler Oy shall replace a faulty product with a new equivalent product or up to the price of the defective product.

Maler Oy is not responsible for indirect costs.

HDF interior wall panels - 11mm

Read the instructions carefully before the installation of the interior wall panels

Before installation

- Note that the interior wall panels are meant only for indoor use and they must not be in direct contact with moisture.

- Interior wall panels are not suitable to be installed to the ceiling.

- Any faults in the materials shall be reported to prior to the installation.

- The interior wall panel suits only for premises where the room temperature and humidity are normal, approx. 20°C, and the relative humidity is approx. 40%, i.e. the walls and the ceiling of the room shall be dry with window glasses and doors installed.

- Interior wall panels should not be exposed to continuous temperatures of over 70°C.

- The temperature and humidity of the interior wall panels shall be let to stabilise to the same temperature and humidity with the installation environment for three days before the installation. The packaging does not have to be totally removed. It is enough that you make a hole to the ends of the packages from where the humidity can be removed.

- Large surfaces should be made of the same production batch. The batch number can be found on the bottom interior panel of the package.

Installation

- The product is oversized, which allows a small tear in the film surface and skew (2 cm) within the dimension. Sawing the end cuts of the product, you make a successful installation and a sleek finish.

- The interior wall panels can be attached to the top of the supporting rails, if the width of the bottom rail is at least 70 mm and the distance from centre to centre is 600mm.

- Interior wall panels must be installed parallel to the joists.

- To facilitate the installation, bring the board slightly over the already installed board. Pull the board backwards until the boards are at the same level, and push in to the tongue and groove joint.

- Using a spirit level the panels can be installed straight. Installing the first panel straight is important to make the installation progress correctly.

- Tongued and grooved wall panels are attached with a staple gun. The distance between the staples should be approx. 200 mm.

- Use at least a 22 mm long, 11 mm wide and 1,6 mm thick staples. The staple is shot diagonally to the lower intruding tongue of the female groove.

- Leave a minimum expansion room of 12 mm between the interior panels and the wall or some other surface limited to the panel. If the length or the width of the face is over 6 metres, add 2 mm of the expansion space for each extra metre.

- The wall sockets can be be raised to the same level with the wall surface with a heightening ring.

- The seam is covered by ceiling mouldings, baseboards and universal mouldings.

Maler Oy shall replace a faulty product with a new equivalent product or up to the price of the defective product.

Maler Oy is not responsible for indirect costs.

SPA Wall panels

Read the instructions carefully before the installation of the wall panels

Before installation

Storage

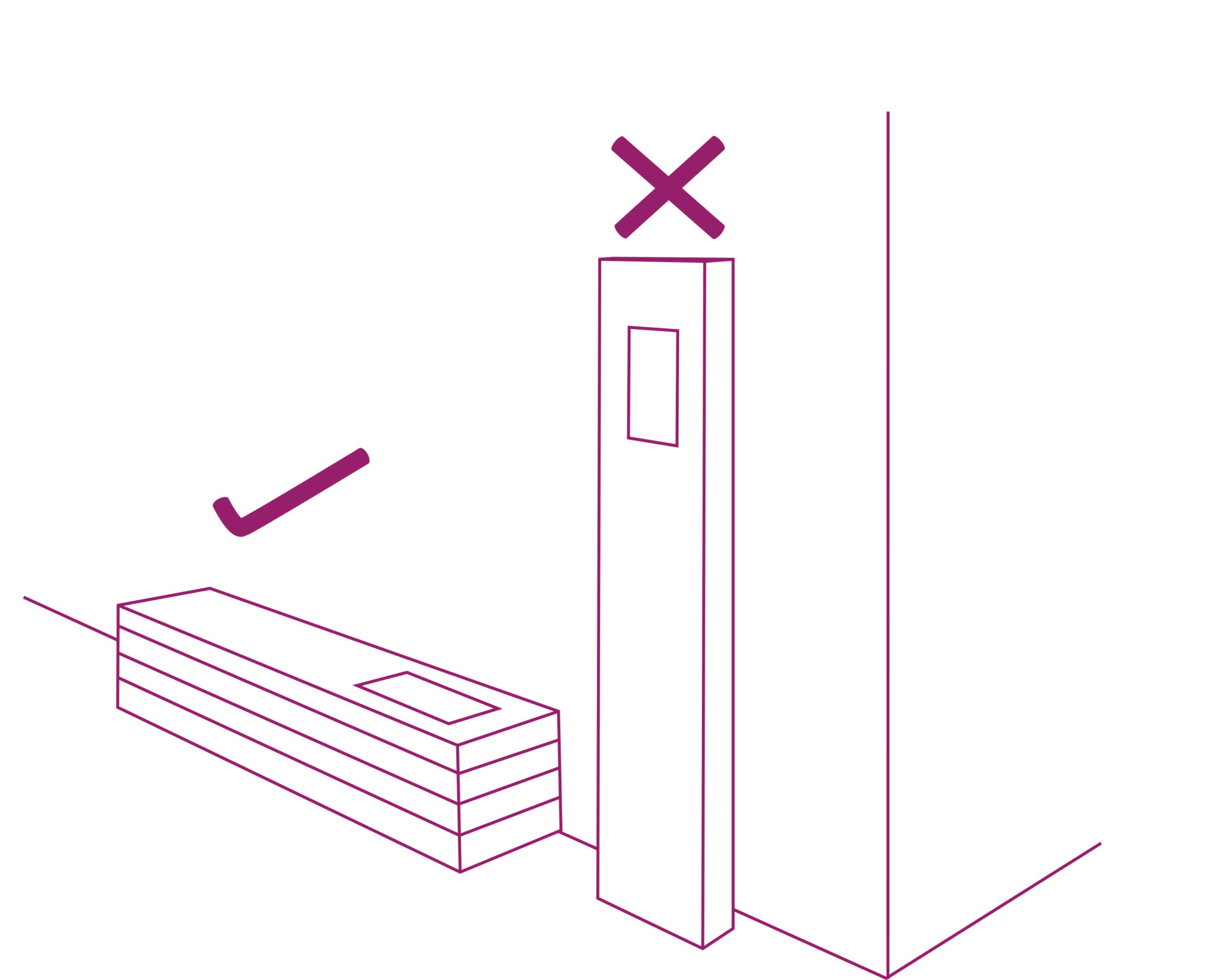

- To avoid deformation in the product, it has to be collocated in a horizontal way.

NB: For shower rooms, moisture insulation is always required.

More instructions on how to install panels in wet rooms can be found at the end of the page

Background

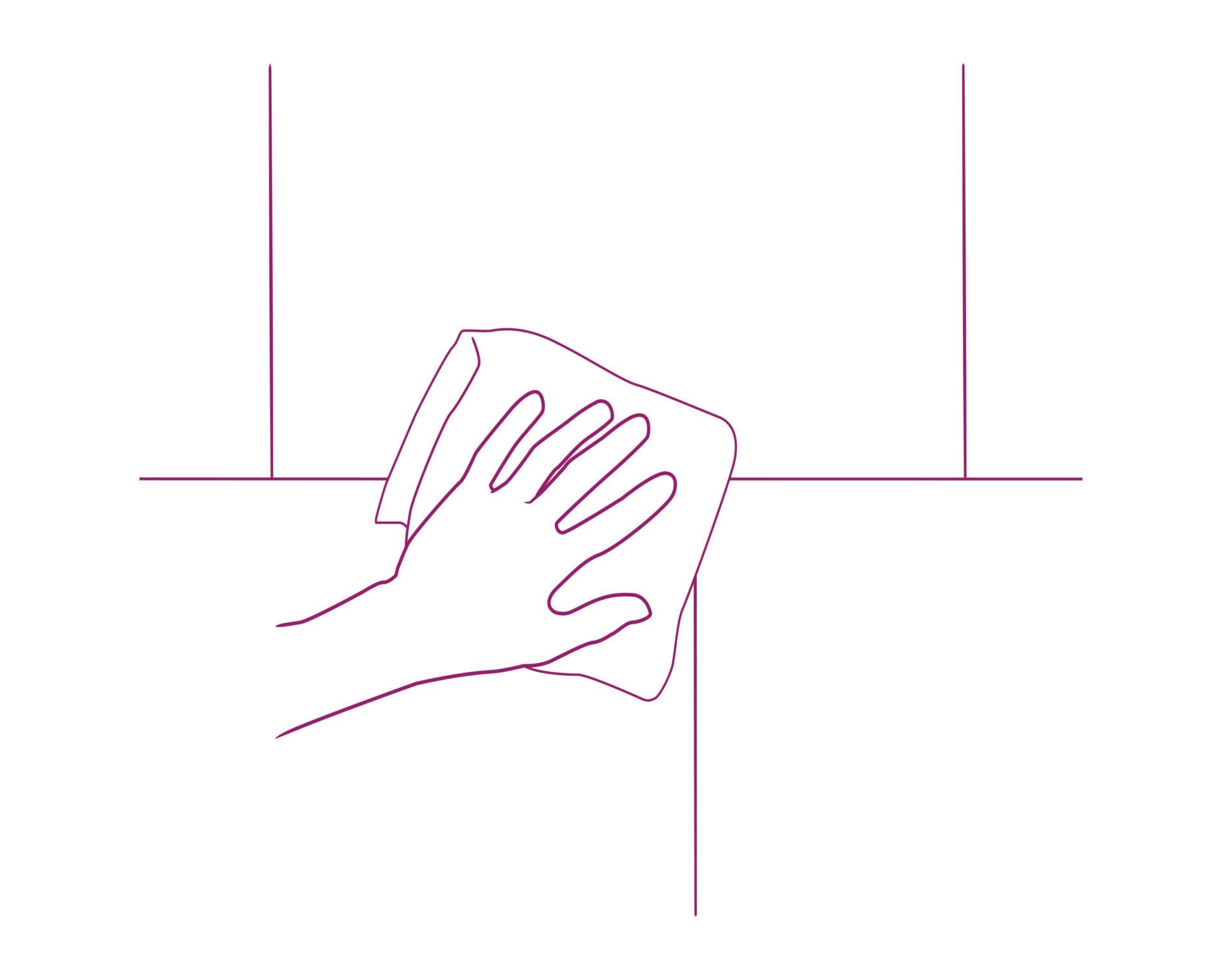

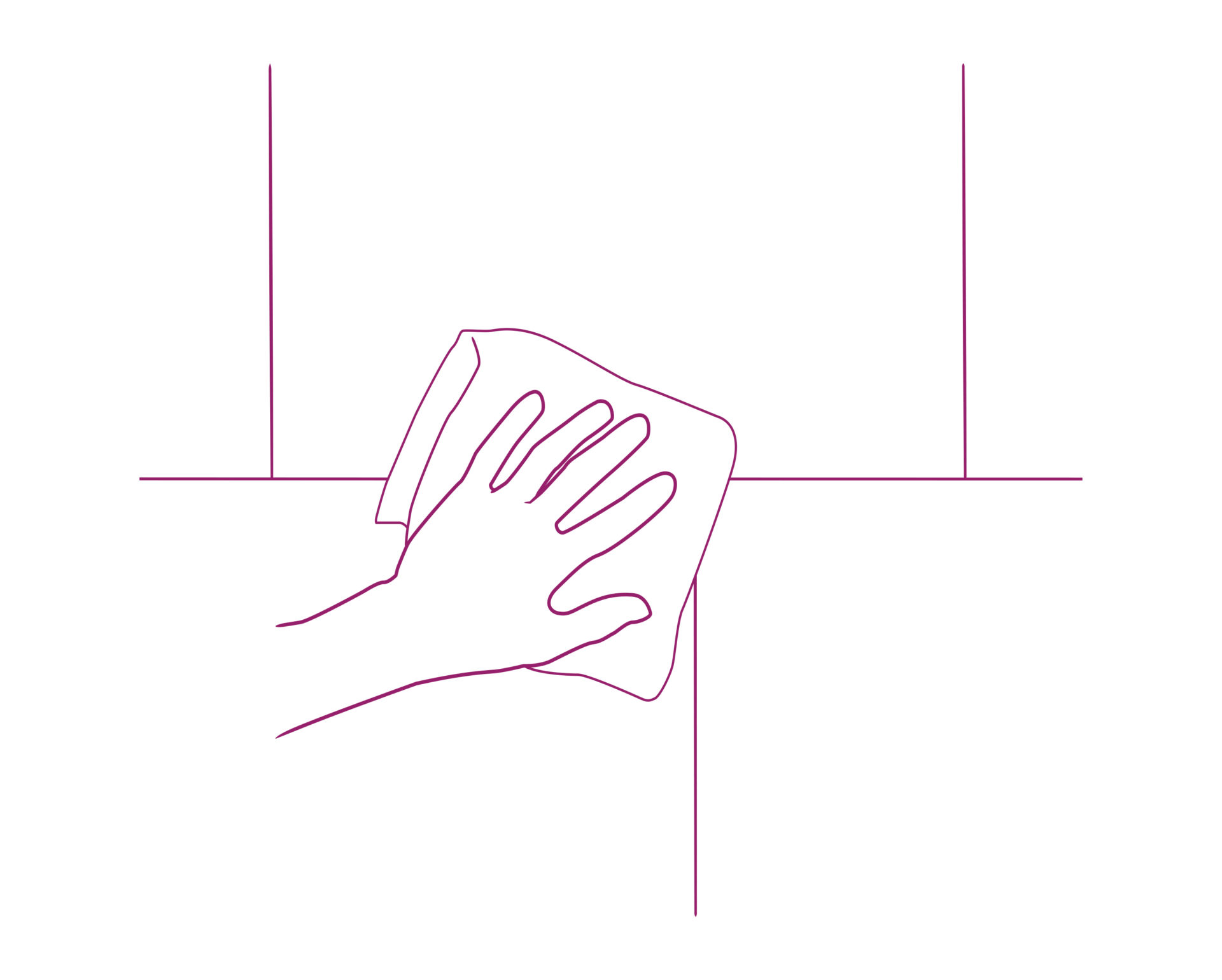

Clean the surface

Be sure that the surface is clean and out of greases.

Preparation of the wall

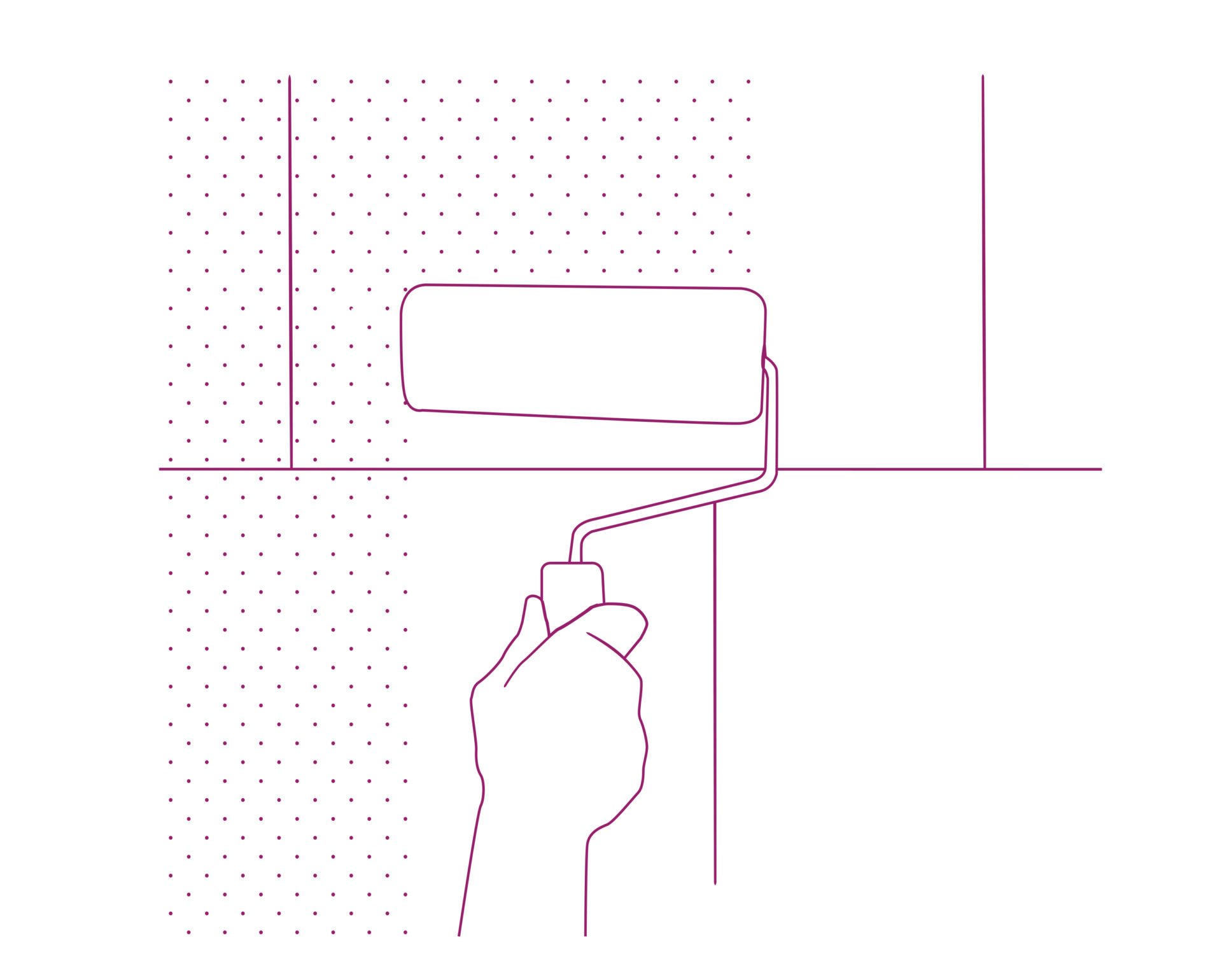

ART SPA Wall panels can be installed directly on many surfaces. If your wall is not porous (because is not concrete, plaster, wood…), it is ready to start working.

Wall perfect to start working

If your wall is not porous (because is not concrete, plaster, wood…), it is ready to start working.

Installation

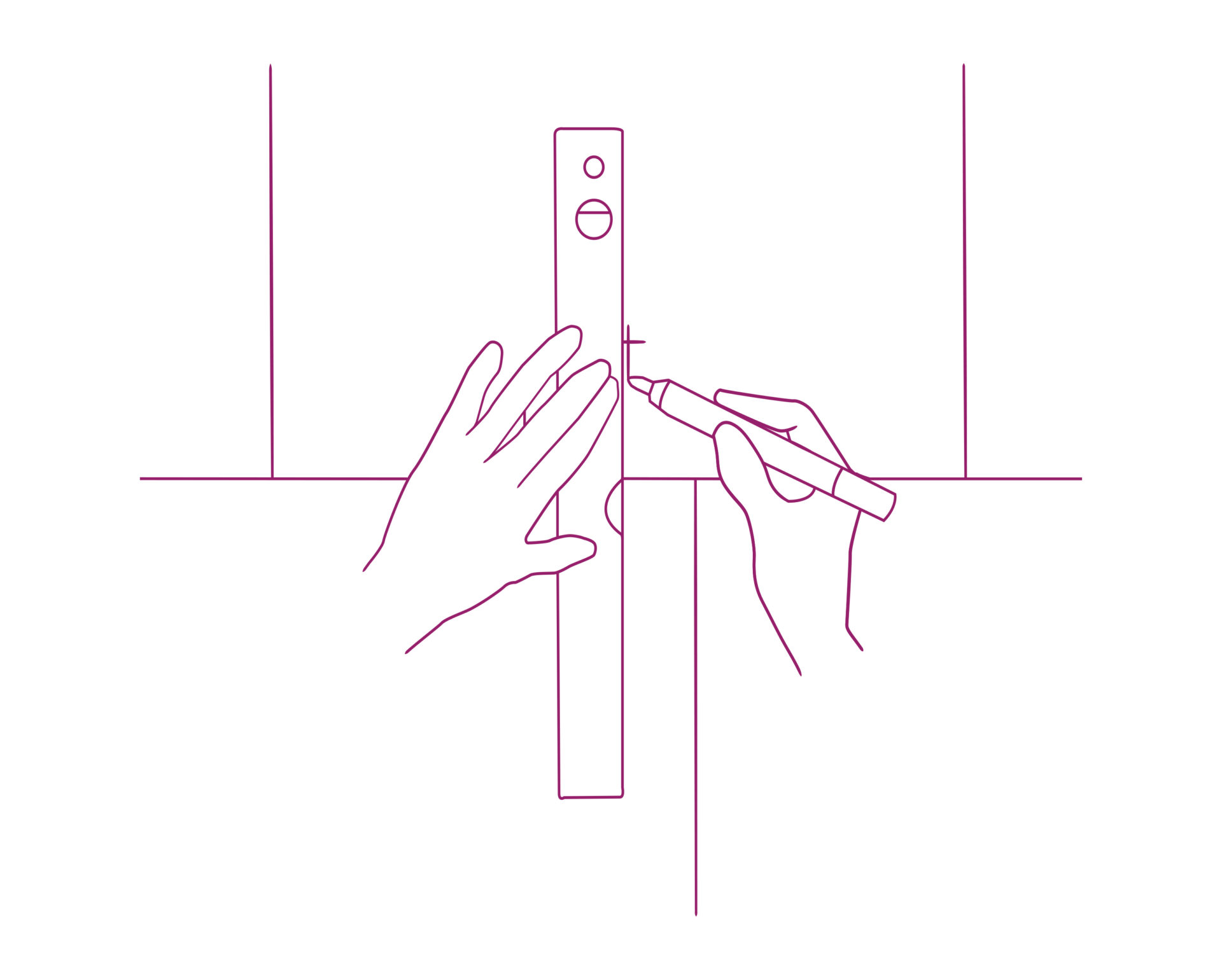

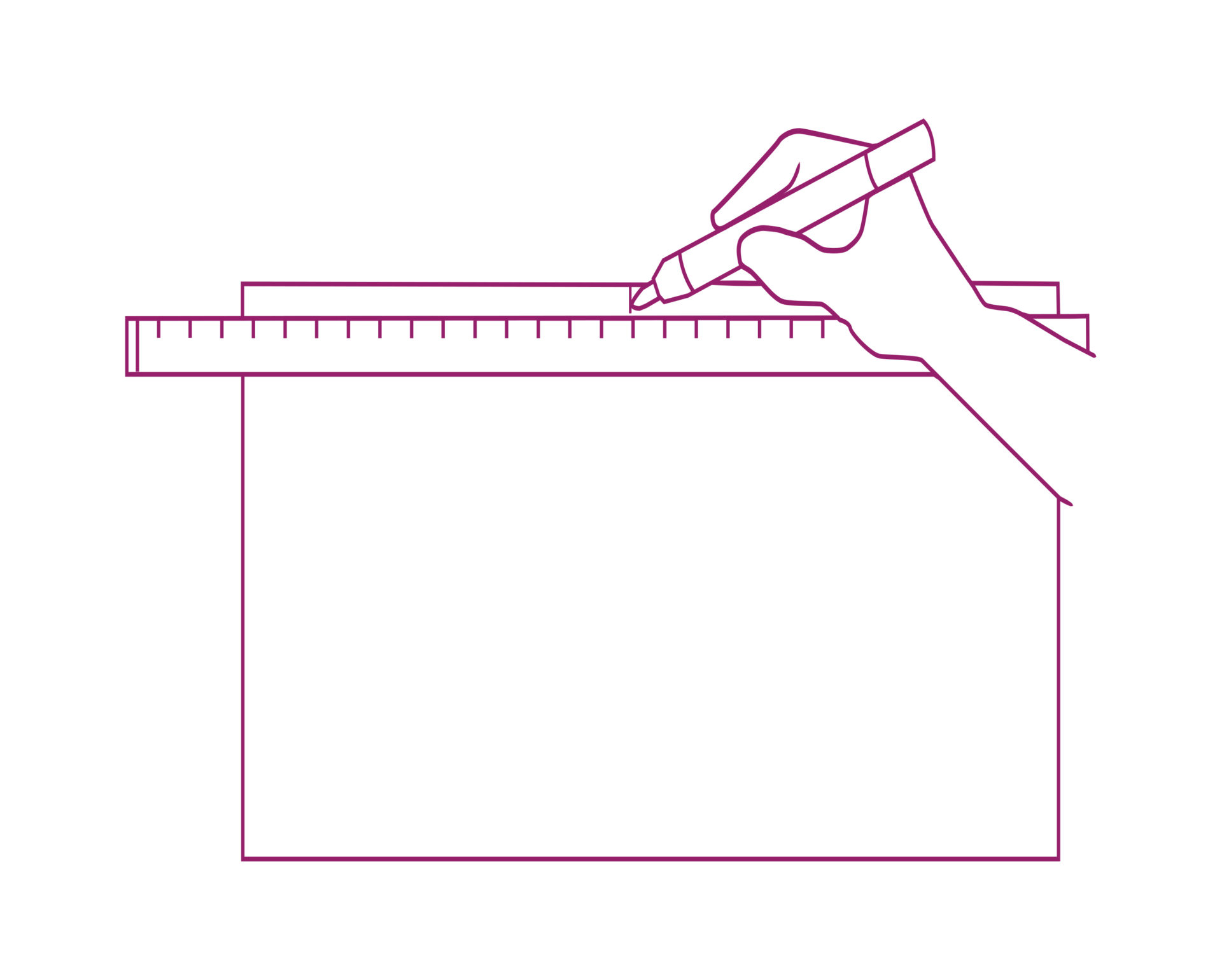

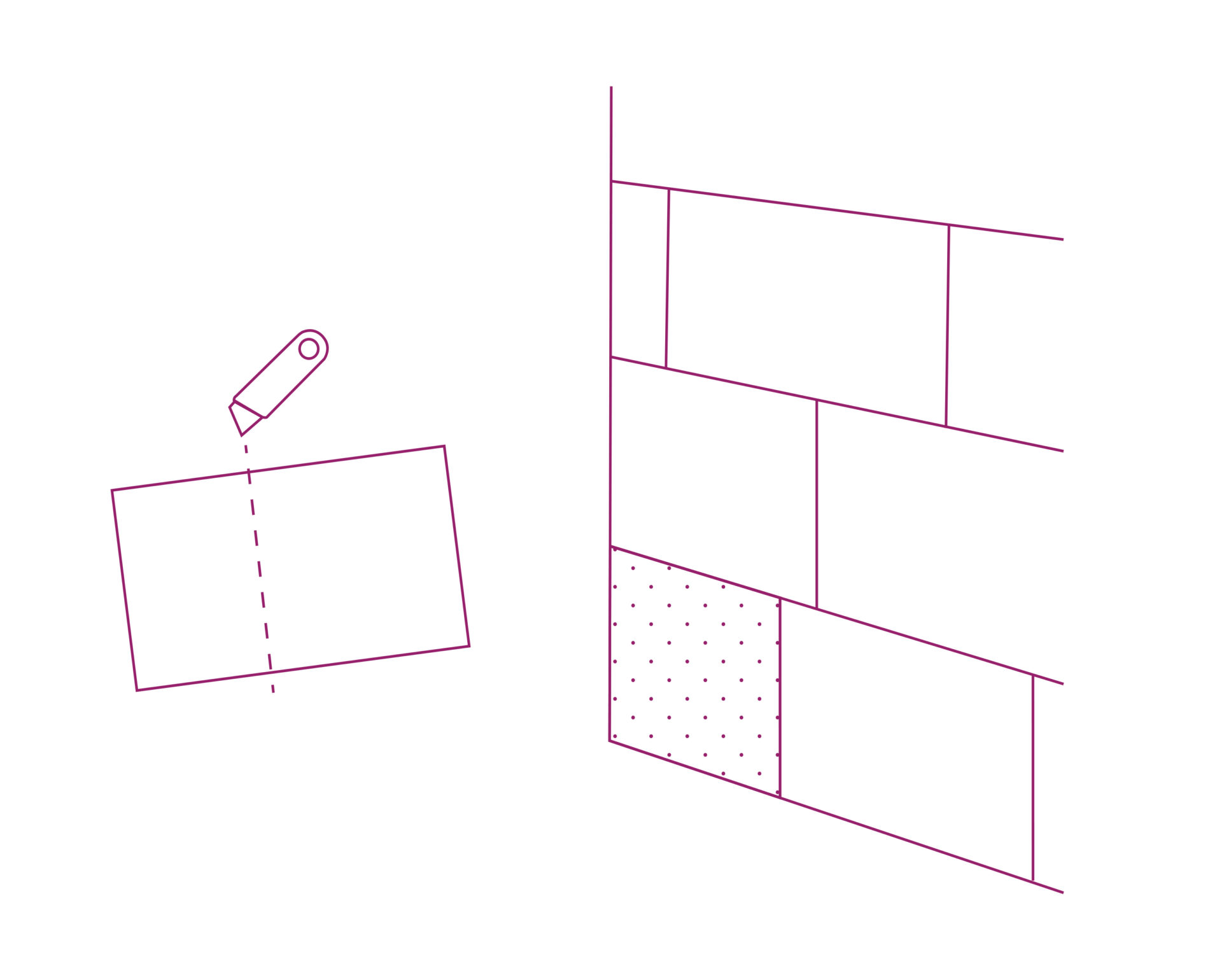

Mark the center of the wall

Mark horizontally and vertically the center, you will obtain 4 angles of 90º, this will help to have a reference to put the first tile.

Apply the installation glue

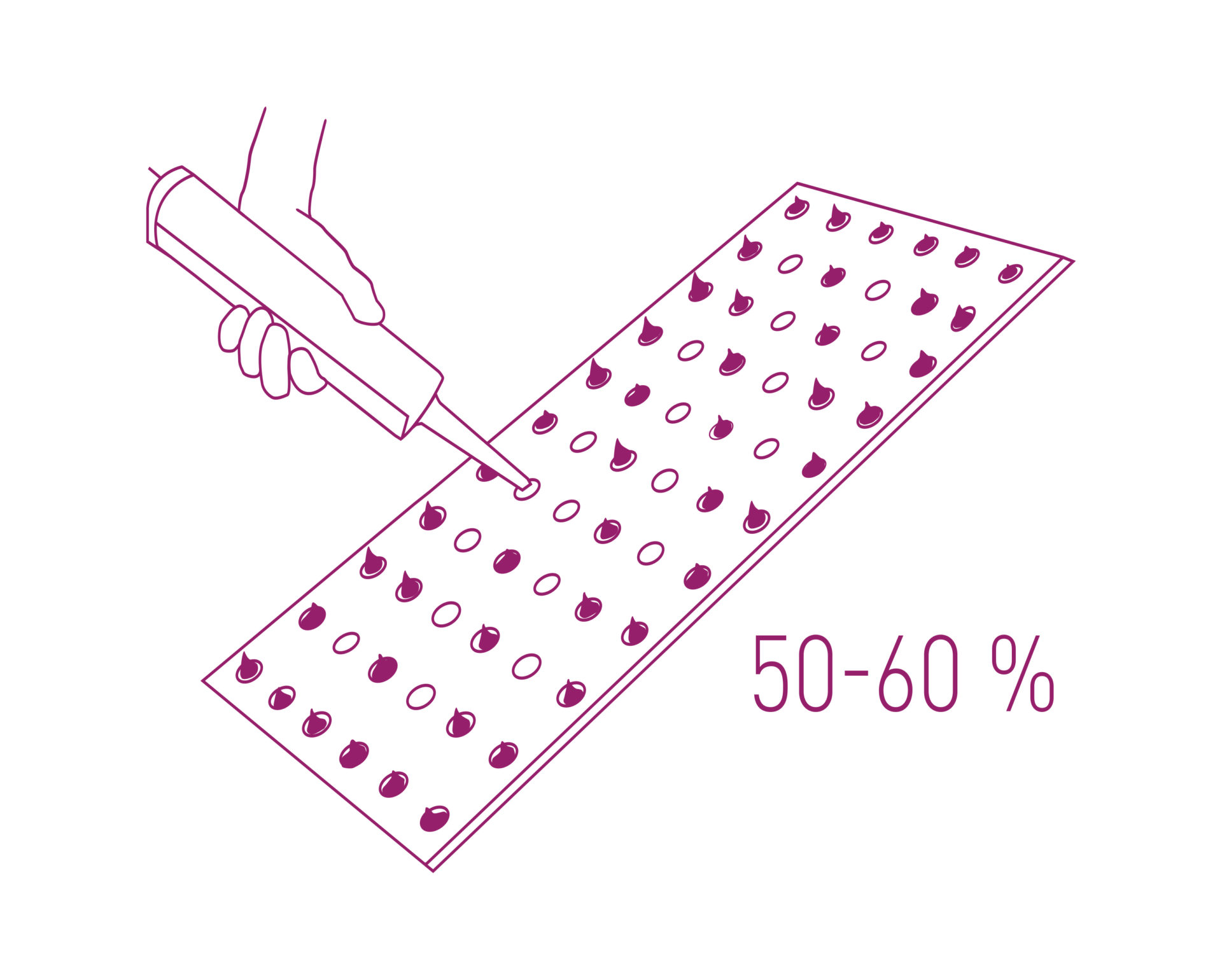

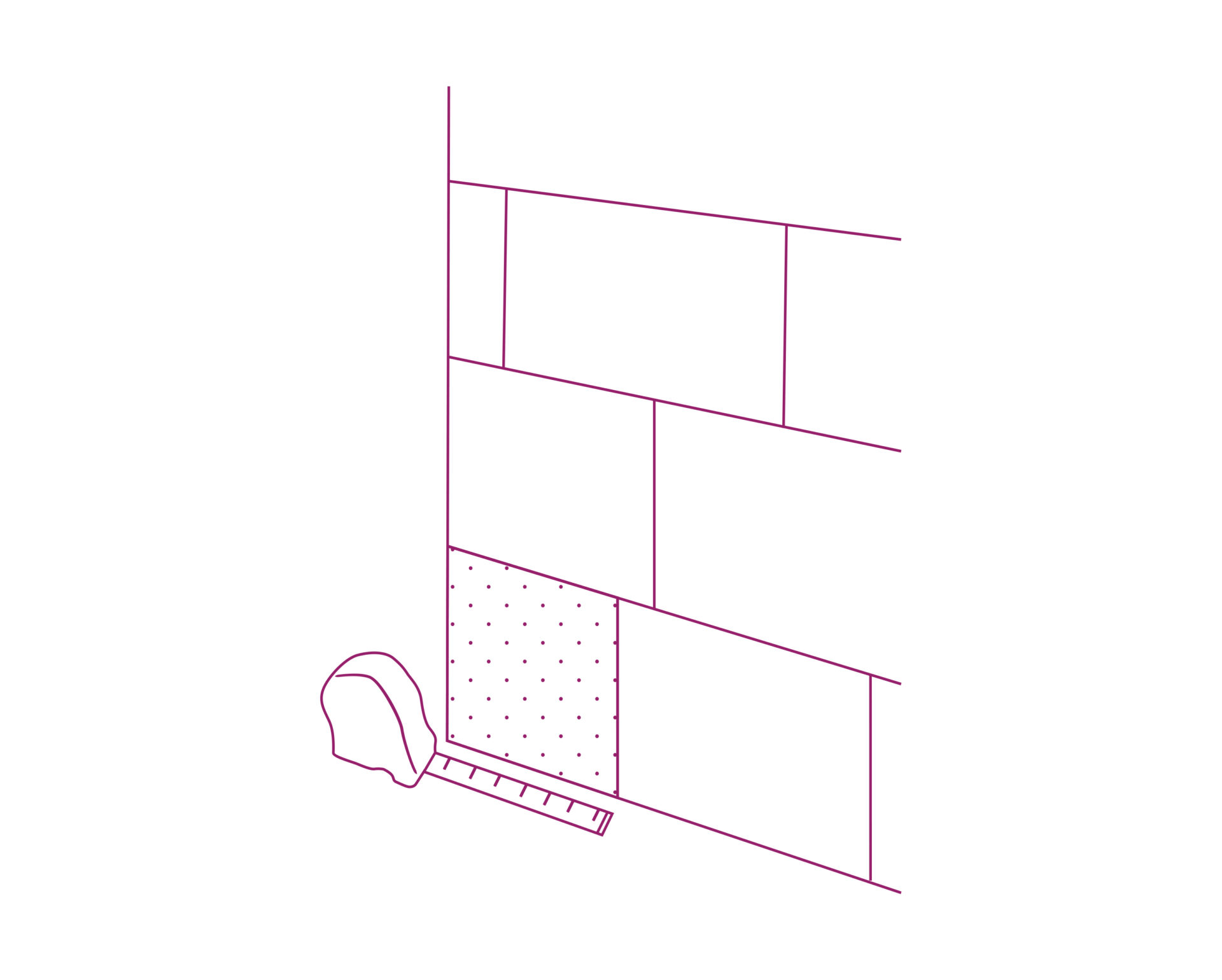

Each tile has an adhesive foam with holes for the installation glue to get the optimum adherence. It is recommended to apply installation glue in the 50% or 60% of the holes.

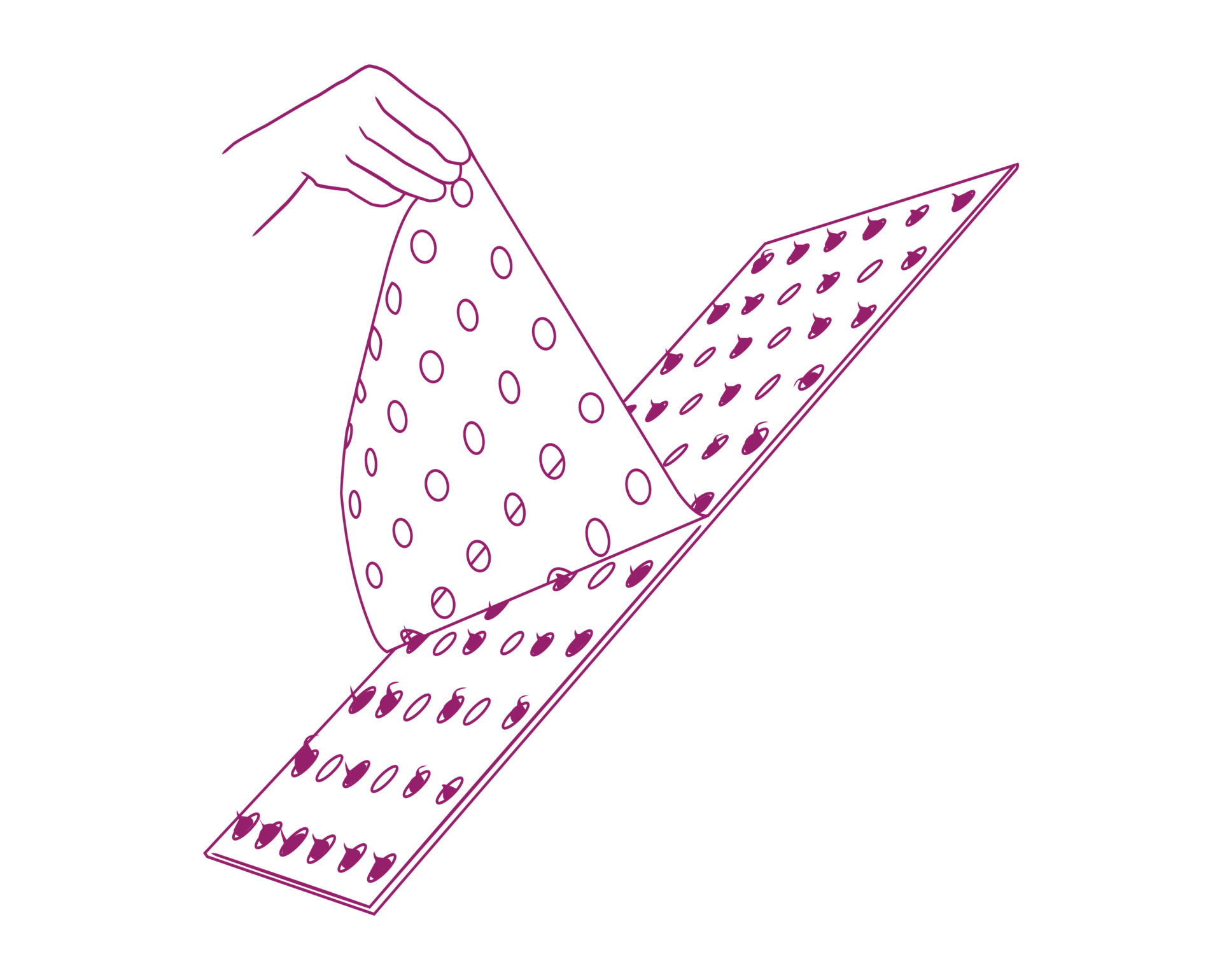

Remove the protector film

Take off the auto-adhesive protector paper to stick the tile over the wall.

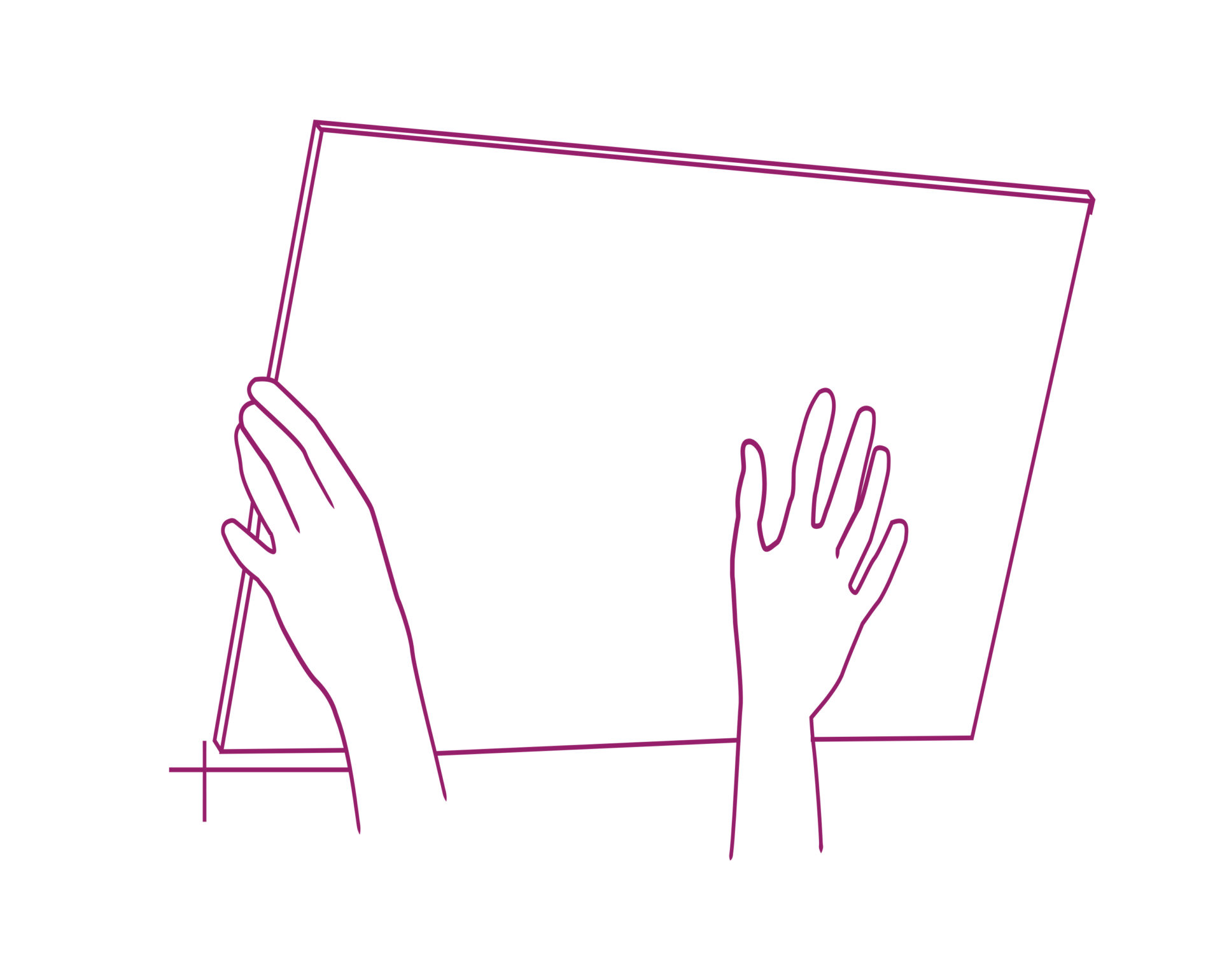

Stick the tile

ollocate the first tile in one of the corners of the marked cross in the center of the wall. Apply during a few seconds a light pressure in the tile from the exterior to the center to get stacked.

Verify that the tile is alienated

Check with a leveler that the first tile is alienated with the center.

Mark the center of the following tile

Collocate the following tile alienated with the center of the wall

Using the center marked cross and the first tile to get oriented, stick the tile below the first one.

Collocate the following tiles

Measure the necessary cut

When installing the last tile, measure the cutting point of the piece of tile needed on the wall.

Cut the excess with a cutter

Using a regular tile, mark the space necessary and cut the excess of the tile just with a cutter.

Collocate the cut tile

Apply installation glue to the holes on the backing and stick the cut tile on the corner.

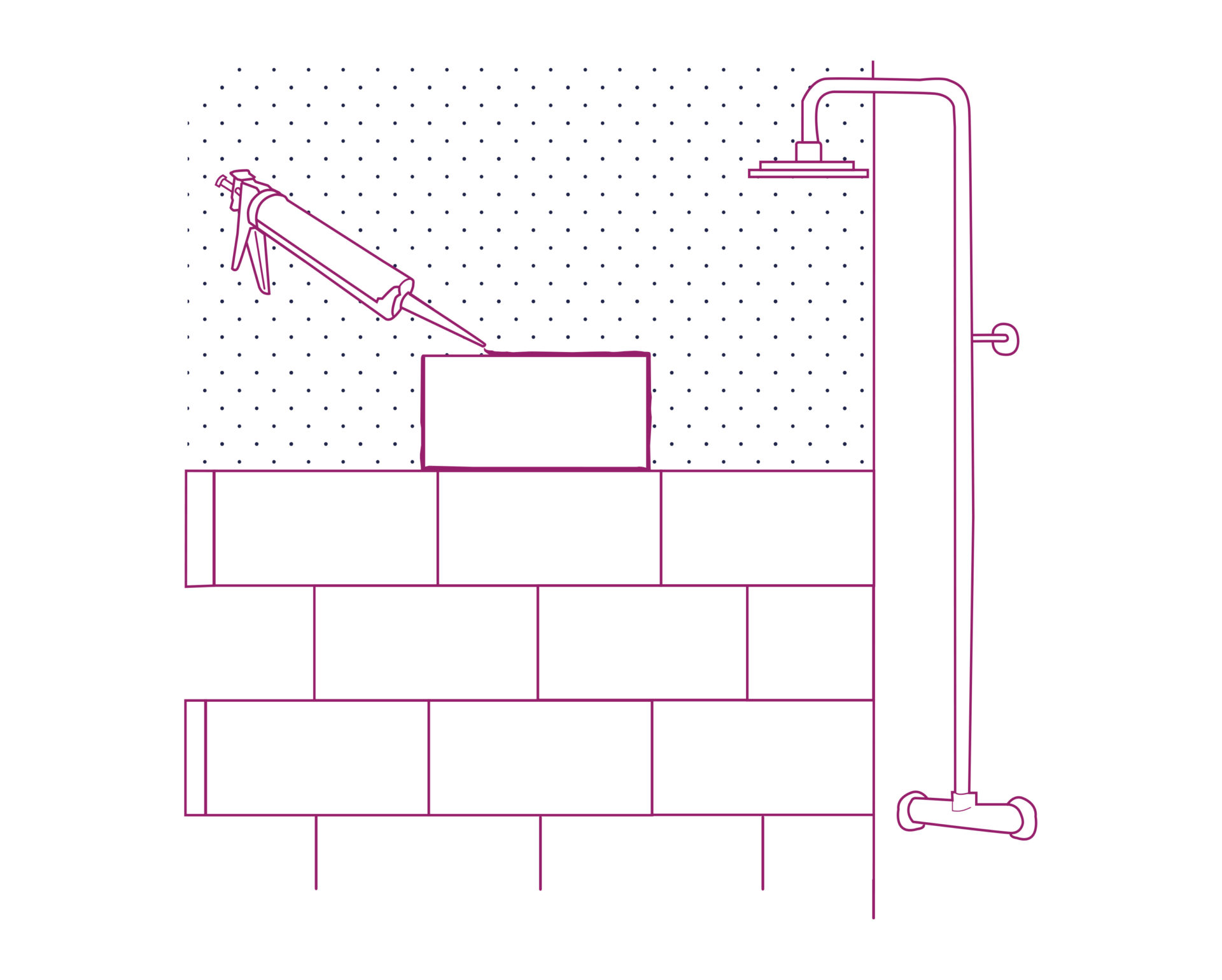

Shower installation

N.B. For shower rooms, moisture insulation is always required.

Clean the surface

Clean it with alcohol and be sure that the surface is clean and out of greases.

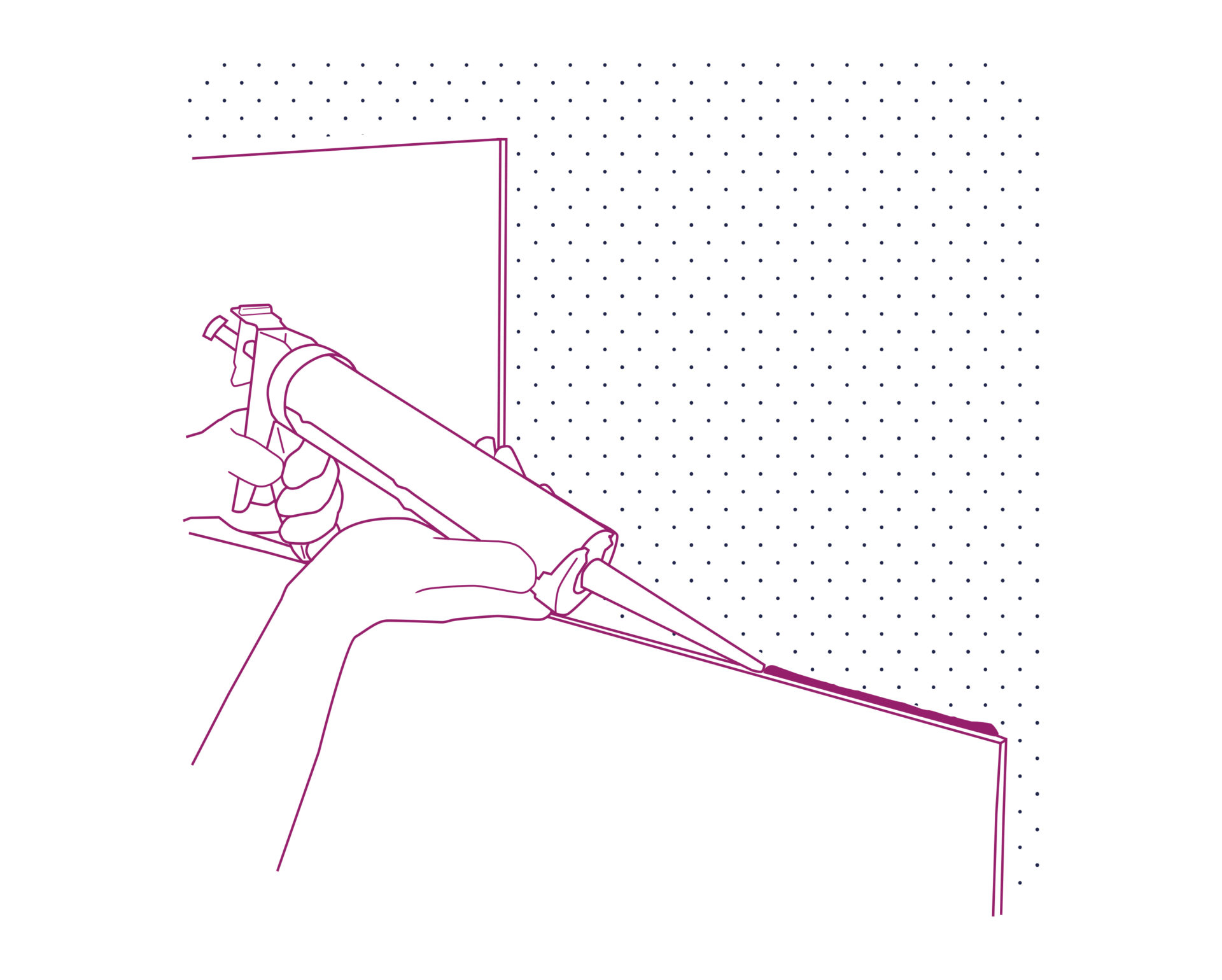

Apply sealant silicone

Apply sealant silicone around the perimeter of each tile before its installation.

Remove excess

Remove the excess silicone with the finger

Art spa wall panels maintenance instructions

The coated Easy Cover Pro texture is hard and resistant and does not need to be polished, varnished, waxed or brightened separately.

Additional processing do not improve the longevity of the product or improve its properties.

Do not use abrasive products or compounds such as ammonia, solvents or other strong substances for cleaning.

These things mentioned above can change product properties such as brightness or color. If you use other cleaning products, test the suitability of the product first.

Maler Oy shall replace a faulty product with a new equivalent product or up to the price of the defective product.

Maler Oy is not responsible for indirect costs.